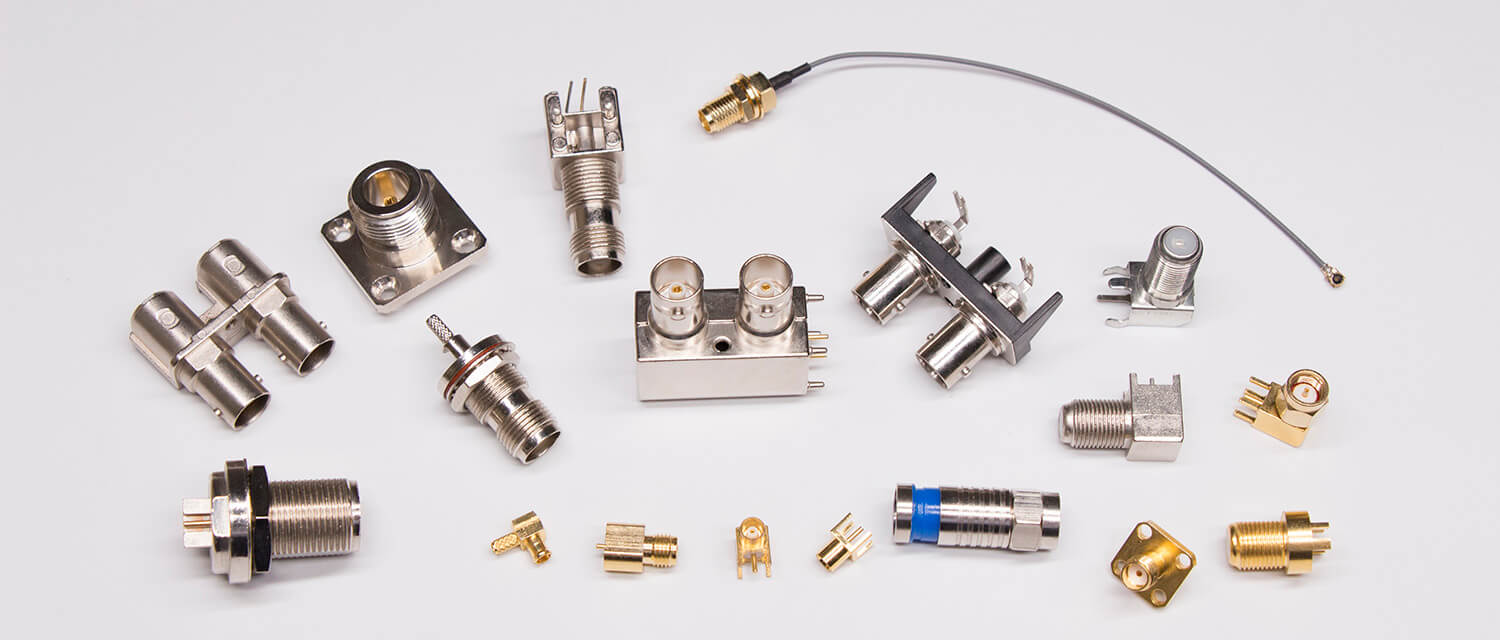

The structure of waterproof connector is generally divided into metal contact conductor and shell metal.

The different between Metal and plastic (nylon TA66) shell :

Mechanical life: The mechanical life of waterproof connector refers to the number of times of plug and pull, and the industry standard is usually 500 to 1000 times.The contact resistance, insulation resistance and withstand voltage of the waterproof connector should not exceed the specified standard value when the mechanical life of the waterproof connector is reached. There is little difference between the metal waterproof connector and the plastic connector.

Behaviour of electricity: Rated voltage, rated current, contact impedance, insulation resistance, etc., according to the required standard value, this metal is the same as the plastic shell.

Enviromental parameter : The main environmental parameters are ambient temperature, humidity, rapid temperature change, atmospheric pressure and corrosion environment. In the use and storage of waterproof connectors, the environment in the process of transportation has a significant impact on its performance, so it is necessary to choose the corresponding metal shell according to the actual environmental conditions will be better than plastic.

Termination Method: Termination method refers to the connection between the hardware contact and the wire and cable of the waterproof connector male and female connector. The metal as same as plastic shell, it is divided into solder, crimp, clamp, pierce and screw.

Comprehensive analysis shows that there is little difference between metal and nylon TA66 plastic shell except for shielding function of connector. The cost of plastic is lower than that of metal shell, and the structure is more reasonable.