There are pointed and round BNC connectors on the market, which one is better?

According to the MIL-C-39012 standard, the angle of the bevel of the pin end is allowed to be between 55 degrees and 65 degrees. The round head process is based on the round head can be inserted at different angles to expand the contact area. It is not easy to contact The contact surface is small and the spark effect is improved; this can’t tell which is better. The judgment of Z is to remove a pin and cut it from the middle. See the material Z inside to explain the problem;

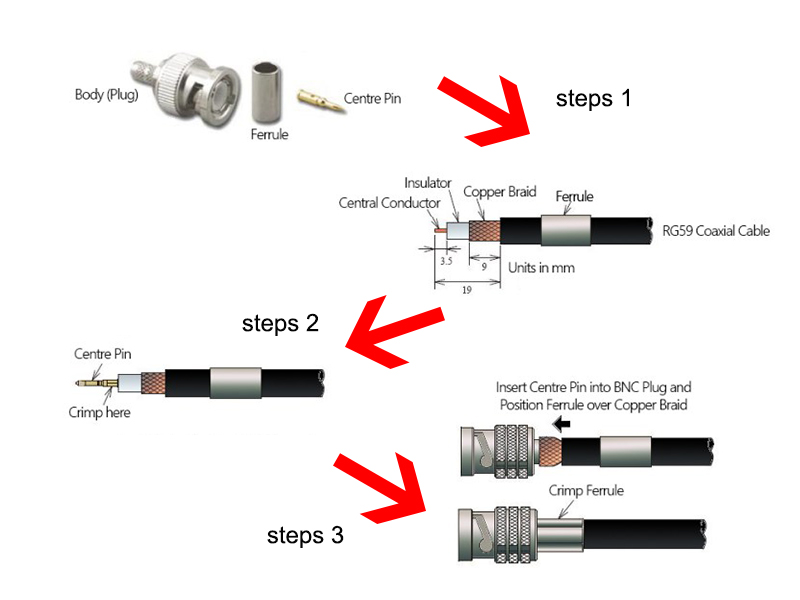

What are the main parts of the BNC connector ?

A BNC connector is composed of 11 parts in total, each part has its irreplaceability, and Z mainly affects the contact resistance and corrosion resistance of the BNC connector used; generally, the inner conductor is required to be 1.5mΩ outside The resistance is 1mΩ; the corrosion performance depends on the quality of the coating and the material used; if the material is poor, it is easy to jump off.

The pin of the BNC connector is often loose. What causes it?

The main reason for the loosening of the pins of the BNC connector is that the insulating material used may not be PTFE and the pins are straight; the melting point of the general solder is between 183℃ and 231℃, and the PTFE material It has good heat resistance and can be used for a long time at a high temperature of 260℃ and a short-term use at a low temperature of -268℃. When heated to 415°C, it decomposes slowly, and generally soldering will not cause the pins to loosen.

There is also a good BNC connector that is designed with a resistance ring in the middle of the pin to prevent the pin from sliding back and forth. This needs to be disassembled before you can see it. A simple method is to use a soldering iron to solder the pin for a long time. , If the glue loosens easily, it means that the temperature resistance is not enough.

What is the difference between the shielding rings of BNC connectors?

The shielding ring of the BNC connector with glue and quartet products are mainly seen in low-priced products. The glue is to ensure the toughness of the interface and reduce the amount of metal used. The quartet is because of the alloy material used. The material is relatively brittle. Generally, alloys and copper connectors with better materials use a six-way structure without rubber pads, so six-way connectors are better when buying a BNC connector.