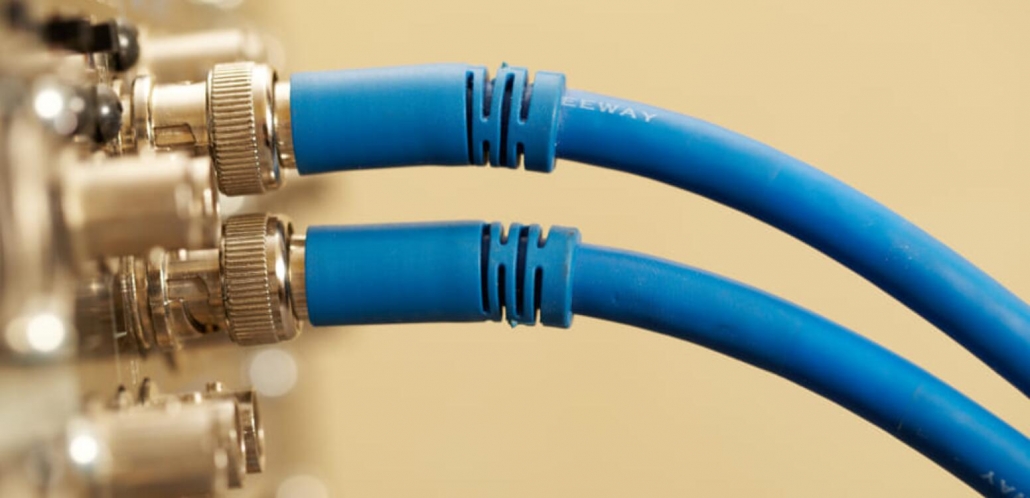

BNC plug, also called Q9 head, is a standard coaxial cable connector, generally used in video surveillance engineering and network engineering. It is used to realize the anti-interference connection from the device to the cable or from the cable to the device.

The characteristic impedance of the BNC head used in video surveillance is 75 ohms, and the characteristic impedance of the BNC head used in the network cable is 50 ohms. At present, the use of network cables has been increasingly replaced by twisted pairs and optical fibers, so most of the BNC heads are used in the field of video surveillance.

The two ends of the coaxial cable are connected to the T-type BNC connector through the BNC connector, and the network card is connected through the T-type BNC connector. When using the coaxial cable, you need to make BNC connectors at both ends of the coaxial cable.

The BNC connector includes: BNC-T type head, used to connect the computer network card and the cable in the network;

BNC barrel connector, used to connect two thin cables into a longer cable;

BNC cable connector, used for welding or screwing on the end of the cable;

BNC terminator, used to prevent the signal from being reflected back after reaching the cable fracture and causing interference. The terminator is a special connector with a carefully selected resistance that matches the characteristics of the network cable. Each terminator must be grounded.

Introduction to installation methods: BNC sub-welding and welding-free

As the name suggests, the soldering type is fixed with soldering iron and soldering tin. This is the most common form used in China. Soldering can be divided into British and American according to the shape. According to the material, it can be divided into cored, zinc alloy and copper of.

There are two types of solder-free: one is tightening with screws, that is, the middle axis wiring has a screw for quick connection. The disadvantage is that the contact is easy to be oxidized and the contact is poor. The advantage is that the requirements for the cable are not high. The specifications of the cables are quite uneven, so the domestic welding-free products are also commonly used; the other three have higher requirements for cables, and they are generally used in foreign countries, namely the straight screw type and the cold pressed type. , Squeeze type;

The straight screw type does not require crimping tools. After the coaxial cable is stripped to a certain length, it can be fixed and contacted by rotating it clockwise. The advantage is that it is easy to install and use, but the disadvantage is that the cable requires specifications and standards.

The cold press type is crimped by special cold press pliers, similar to the crimping crystal head. The advantage of this connection method is that the contact effect is good, it is convenient and fast, it is the fastest method for mass connection, and it is more reliable and durable. The disadvantage is Requirements and standards for cables.

The squeeze type is a crimping method recently introduced from abroad. Its crimping effect is similar to that of the straight screw type, but it has stronger waterproof and back tension and is more suitable for use in harsh environments.