Rosenberger of Germany introduced the HSD connector in 2007 to meet the then-urgent needs of the automotive industry for high-speed data transmission connection technologies, such as in-vehicle audio, video, telephony, etc. HSD connectors use axially placed pin-hole contact technology to provide high-speed, reliable signal transmission with data transfer speeds of up to 1 Gbit/s.

Now Rosenberger has launched the HSD 2.0 and HSD+ standards. HSD 2.0 standard presents the first dual data transmission channel design with higher reliability and faster data transmission speed. The HSD+ standard, on the other hand, further enhances the transmission speed and bandwidth based on ensuring compatibility with existing standards, reaching a high-speed data transmission of 8 Gbit/s.

HSD connectors have become necessary for automotive, telecom, smart home, and other fields, providing fast, efficient, and reliable data transmission services for many applications.

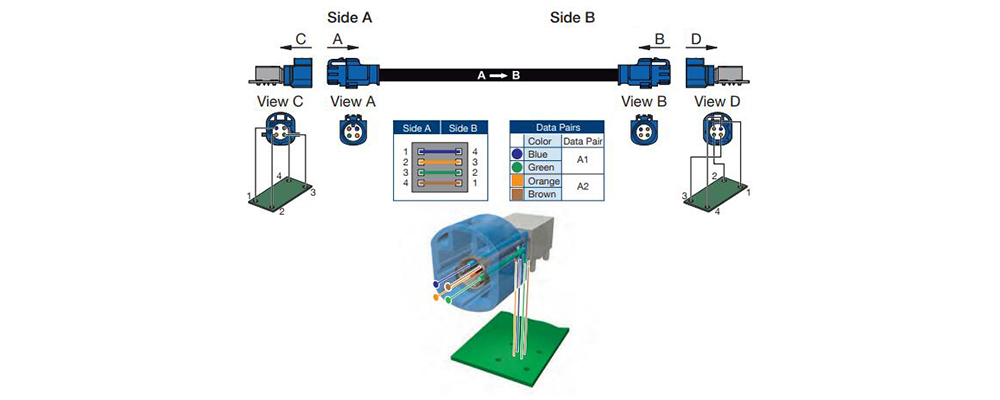

Mechanical Structure

Connector body: The connector body is high-strength alloy steel for robust construction and high reliability.

Contact parts: The spring is used to apply pressure to the contact parts to ensure good contact.

Spring: The spring is used to apply pressure to the contact parts to ensure good contact.

Dust cover: The dust cover protects the connector from damage by the external environment.

HSD connectors also have other mechanical structures, such as sealing rings, constant pressure structures, and locking mechanisms. These structures ensure the reliability and sealing of the connectors and guarantee stable and reliable connections even after long-term use in harsh environmental conditions.

Basic Properties

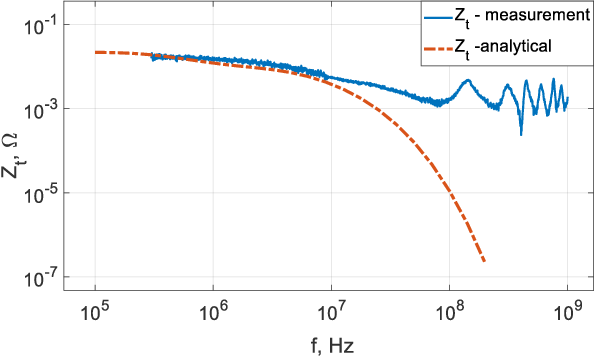

Transmission speed: The data transmission speed of the HSD connector can reach 8Gbit/s, which can meet the demand for high-speed data transmission.

Impedance: The impedance of HSD connectors is usually 100 ohms to ensure the stability and reliability of signal transmission.

Compatibility: HSD connectors must be compatible with similar connectors to ensure interoperability between connectors and consistent with the corresponding standard specifications.

Plugging force and contact impedance: The pinhole contact design of HSD connectors is excellent, enabling meagere plugging force and consistency impedance, which can reduce signal loss and improve data transmission efficiency.

Good immunity to interference: The HSD connector is designed with a shield to prevent the entry of external interference signals, thus ensuring the stability of the signal transmission.

High durability: The design of HSD connectors enables them to withstand high-frequency insertion and removal operations. Under standard use conditions, they have a lifespan of over 5,000 insertions and removals.

External dimensions: HSD connectors are usually more miniature to accommodate miniaturized designs.

In summary, HSD connectors have excellent high-frequency transmission performance, low plugging force, soft contact impedance, good anti-interference capability, high durability, and waterproof and dustproof electrical performance to meet the harsh data transmission environment requirements.

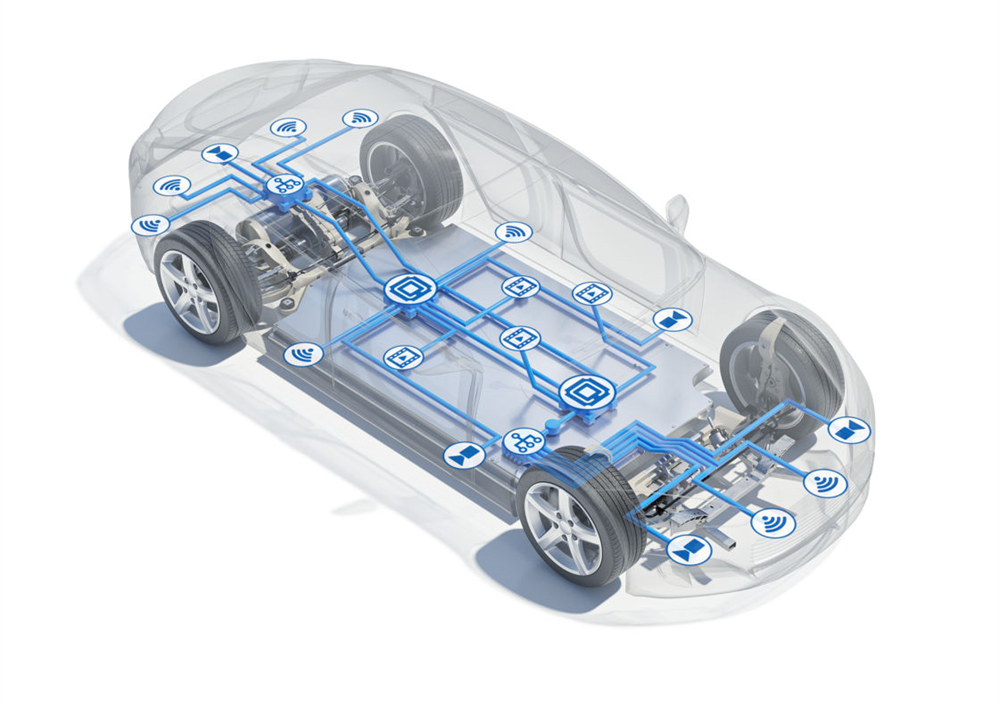

Applications

The following are some typical HSD applications:

In-vehicle audio and video: HSD connectors can connect in-vehicle audio and video devices, such as stereos, DVD players, and terminal displays, to ensure the stability and reliability of high-speed data transmission.

Car phone: HSD connectors can connect car phone devices, such as GPS navigators, Bluetooth phones, etc., supporting high-speed audio, video, and data transmission.

Telecom equipment: HSD connectors can connect to telecom equipment, such as 3G or 4G base stations and network routers, to support high-speed data transmission and communication.

Smart Home: HSD connectors can connect smart home devices such as cell phones, tablets, smart speakers, etc., for audio, video, and data transmission.

In addition to this, HSD connectors are widely used in various fields such as medical equipment, aviation and aerospace, factory and industrial automation, and so on. HSD connectors can provide high-speed data transmission and reliable connectivity solutions with various market prospects in these applications.

Development Trends

With the continuous advancement of technology and the increasing demand for high-speed data transmission, HSD connectors still have broad future development prospects. The following are possible future directions for development:

Higher data transfer speeds: HSD connectors will continue to increase transfer speeds and bandwidth in the future, with HSD 2.0 and HSD+ standards already in place and the potential for higher-speed connectors.

Smaller size: With the trend of the miniaturization of mobile devices and smart home devices, HSD connectors will become smaller and lighter.

Higher water and dust resistance rating: When applied in harsh environments such as automotive and industrial, HSD connectors require a higher water and dust resistance rating to ensure the reliability and stability of the connector.

More new technologies: HSD connectors will also apply more new technologies in the future to improve the mechanical and electrical properties of the connectors, such as 3D printing technology, virtual reality technology, etc. These technologies will bring more possibilities for the manufacturing and application of connectors.

In short, the future of HSD connectors will continue to evolve based on higher speed, smaller size, more comprehensive application scenarios, and higher water and dust resistance levels to provide a more reliable and stable connection solution for various high-speed data transmission applications.