BNC connectors have been a mainstay of the electronics industry for decades due to their ease of use, reliable performance, and secure connections. In this guide, we will explore the history, mechanical construction, electrical properties, and applications of BNC connectors in more detail.

History of BNC connectors

Paul Neill and Carl Concelman developed the BNC connector in the early 1940s for the American radio company. Initially, people used the connectors for cable connections in television and radio to provide stable signal transmission and easy connection and disconnection. Since then, BNC connectors have become increasingly popular in commercial and industrial applications.

Over time, BNC connectors have undergone improvements and optimizations. For instance, the developers introduced 75-ohm BNC connectors to cater to computer networks. Developers have also developed various versions of BNC connectors to suit diverse applications, including straight, flange, and SMT.

Overall, the stability and reliability of the BNC connector in signal transmission, as well as its easy connection and disconnection, make it one of the widely used standard connectors.

Mechanical structure of BNC connectors

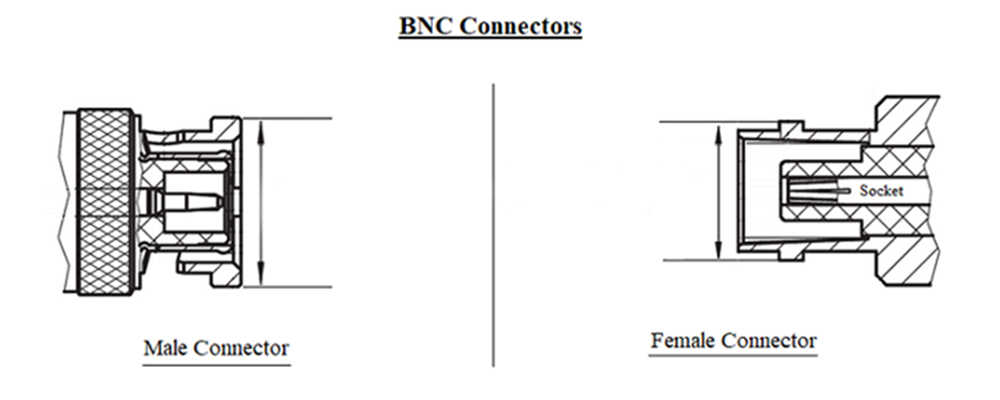

The mechanical structure of the BNC connector consists of two parts: the housing and the internal connector.

The housing is usually made of a metallic material, such as galvanized steel, aluminum alloy, or stainless steel. It is similar in shape to a cylinder with a circular hole with a diameter slightly smaller than the center pin of the connector’s center connector. The end of the housing has a rotatable ring with raised “teeth” to increase the connector’s stability and ensure proper alignment.

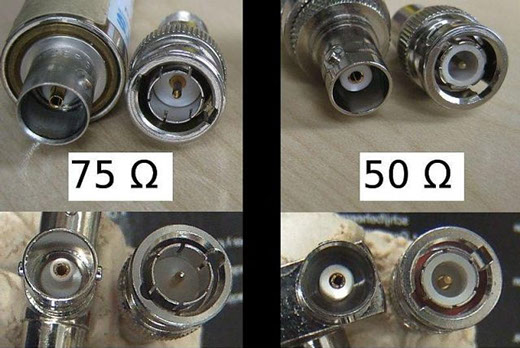

The internal connector is also usually made of metal, such as brass or stainless steel. It has a cylindrical body with a pin in the center. There are two essential pins: a cylindrical one for 50-ohm coaxial cables and a flat one for 75 ohms. The end of the pin may have some slight design variations to ensure proper fit to the coaxial cable.

During connection, the internal connector is inserted into a circular hole in the housing and then secured by rotating a ring on the housing. This mechanical construction gives the connector better vibration resistance and reliability, and it is straightforward to connect and disconnect.

Electrical performance of BNC

Impedance: BNC connector has two standard impedances, 50 ohms and 75 ohms, where 50 ohms is used for applications such as radio and video, and 75 ohms is used for computer networking applications. It must match the cable’s impedance and equipment for optimal signal transmission. The wrong impedance can lead to signal loss, distortion, or interference.

Frequency range: The frequency range of the BNC connector depends on the coaxial cable used and the impedance of the connector, generally between DC and 4 GHz.

Return Loss: It measures the signal reflected from the connector. The lower the return loss, the better the signal transmission. High return loss can lead to signal loss and poor signal quality.

Insertion loss: A BNC connector’s insertion loss is the signal’s loss as it passes through the connector. The smaller the insertion loss, the better the signal transmission quality. The insertion loss of a standard BNC connector should generally be less than 0.2 dB over the DC to 4 GHz frequency range.

Reflection loss: refers to the loss of signal reflected from the connector. The lower the reflection loss, the better the signal transmission quality. Standard BNC connectors should generally have less than -20 dB reflection loss in the DC to 4 GHz frequency range.

Insulation impedance: refers to the impedance between the conductor and the insulation material inside the connector. The higher the insulation impedance, the better the quality of signal transmission. A standard BNC connector should generally have an insulation impedance greater than 1000 MΩ in the DC to 4 GHz frequency range.

VSWR: The ratio of reflected to forward waves on a transmission line, usually used to measure signal transmission quality. The smaller the VSWR, the better the quality of signal transmission. In the frequency range from DC to 4 GHz, the VSWR of a standard BNC connector should generally be less than 1.3.

Common application scenarios for BNC

Radio and TV broadcasting: BNC connectors can connect antennas and radio equipment, such as radio and TV stations.

Ethernet Networks: BNC connectors find applications in Ethernet networks to connect devices such as computers, hubs, and switches.

Instrumentation and measurement: BNC connectors find application in instrumentation and measurement to connect various test and measurement equipment, including oscilloscopes, signal generators, and spectrum analyzers.

Video Surveillance: BNC connectors can connect surveillance cameras and video recorders.

Aerospace: BNC connectors also have a wide range of applications in the aerospace field, such as connecting radar, satellite communication equipment, and sensors for flying vehicles.

Medical equipment: BNC connectors can connect various medical devices, such as electrocardiograms and ultrasounds.

The electronics industry widely uses BNC connectors because they offer easy-to-use, reliable, and secure connections. To ensure optimal signal transmission, one must consider its impedance, return loss, insertion loss, and insulation resistance when selecting a connector. BNC connectors are versatile and find use in various scenarios that require coaxial connections, and their stability and reliability make them the connector of choice in many fields.